Fiber optic cables have revolutionized the way we transmit data, bringing high-speed internet and reliable connectivity to homes and businesses worldwide. These cables are composed of thin strands of glass or plastic fibers, each about the diameter of a human hair. The primary function of these fibers is to carry light signals over long distances, enabling the rapid transmission of data.

The core component of a fiber optic cable is the *core*, where the light travels. Surrounding the core is the *cladding*, which reflects light back into the core to minimize signal loss. The entire assembly is protected by a *buffer coating* that guards against physical damage. An outer jacket provides additional protection and flexibility, making the cables durable enough for various installation environments.

Understanding the structure and function of fiber optic cables is essential for anyone involved in modern communication infrastructure. Whether you’re a business looking to upgrade your network or a homeowner interested in faster internet speeds, fiber optic technology offers unparalleled advantages.

Visit our website to learn more and get started today! Click here.

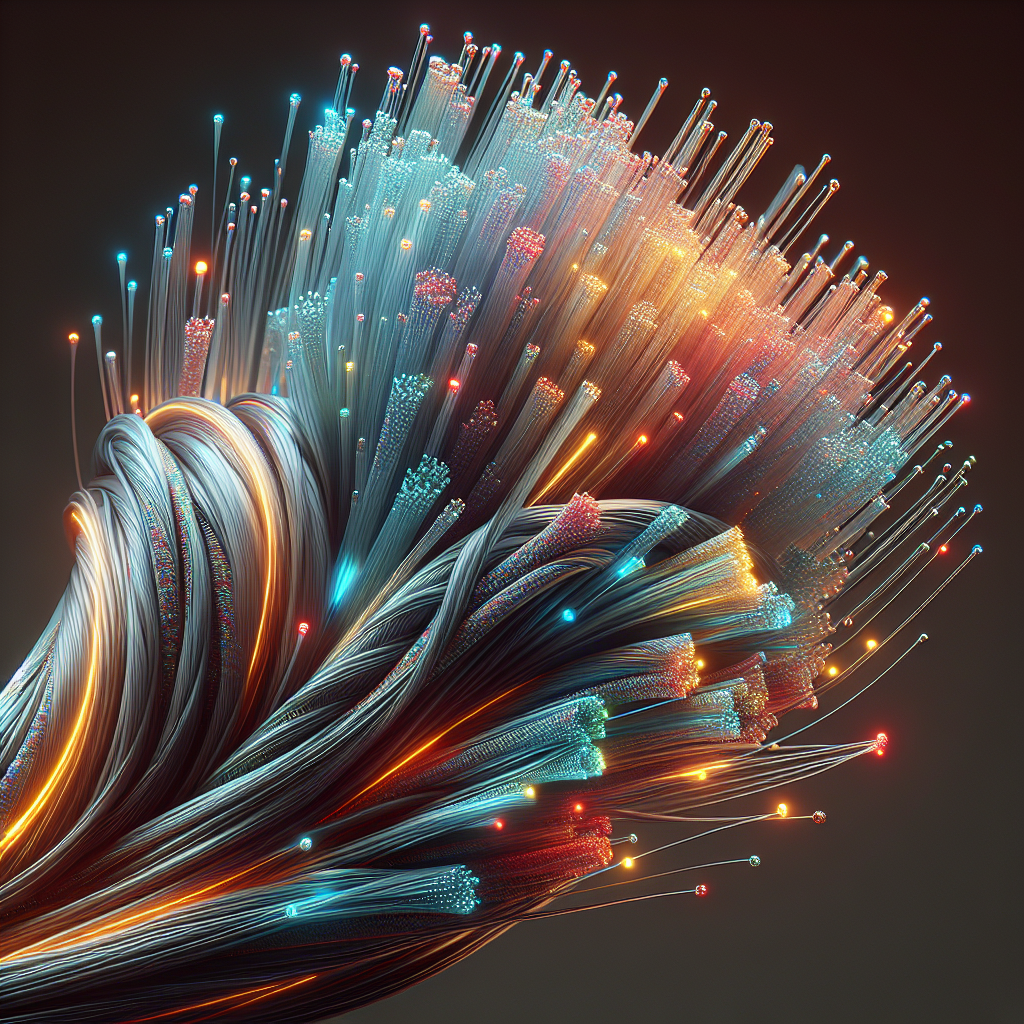

Physical Appearance of Fiber Optic Cables

When you first look at a fiber optic cable, you might notice its sleek and somewhat unassuming exterior. The outer jacket, which can be colored for easy identification, is typically made of durable materials like PVC or polyethylene. This outer layer provides protection against environmental factors such as moisture, chemicals, and physical abrasion.

Upon closer inspection, the cable consists of several layers. Just beneath the outer jacket, you might find a layer of strength members, often made from materials like aramid yarn (e.g., Kevlar). These strength members provide tensile strength, helping the cable withstand pulling forces during installation.

Inside the cable, the core and cladding layers are the most critical components. The core, a thin glass or plastic strand, is where light signals travel. Surrounding the core is the cladding, which has a different refractive index to keep the light signals confined within the core.

Between the cladding and the outer jacket, you may also find a buffer coating that provides additional protection to the core and cladding. The buffer can be either tight or loose, depending on the cable type and its intended application.

Overall, the physical appearance of a fiber optic cable is a combination of robust external protection and intricate internal structure, all designed to ensure efficient and reliable data transmission.

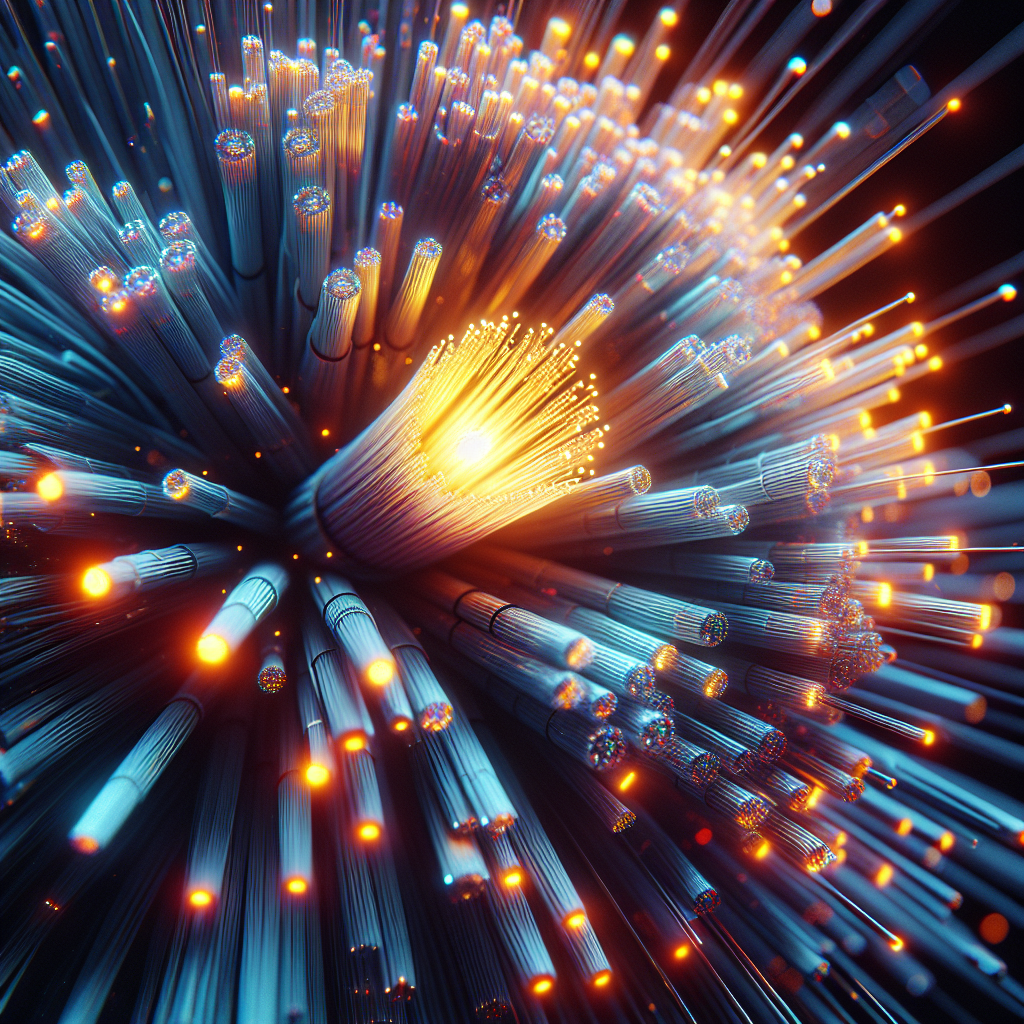

Core Structure of Fiber Optic Cables

The core of a fiber optic cable is the heart of the system, responsible for carrying light signals over long distances with minimal loss. It is typically made of either glass or plastic, with glass being the most common material due to its superior light transmission properties.

At the most basic level, the core is a cylindrical strand, remarkably thin, often comparable to a human hair. The diameter of the core can vary depending on the type of fiber optic cable. For instance, in single-mode fibers, the core diameter is usually around 8 to 10 micrometers, allowing only one mode of light to propagate. In contrast, multimode fibers have a larger core diameter, typically around 50 to 62.5 micrometers, which allows multiple modes of light to travel simultaneously.

The core is surrounded by the cladding, which has a slightly lower refractive index than the core. This difference in refractive index causes the light signals to undergo total internal reflection within the core, ensuring that the light remains trapped and continues to propagate along the cable. The precision in manufacturing the core and cladding is crucial, as any imperfections can lead to signal loss or distortion.

In addition to these primary layers, some fiber optic cables may include an additional coating or buffer around the core and cladding. This layer provides extra protection against physical damage and environmental factors.

Understanding the core structure is vital for appreciating how fiber optic cables achieve their high performance and efficiency in data transmission. It’s this intricate design that makes fiber optic technology a cornerstone of modern communication systems.

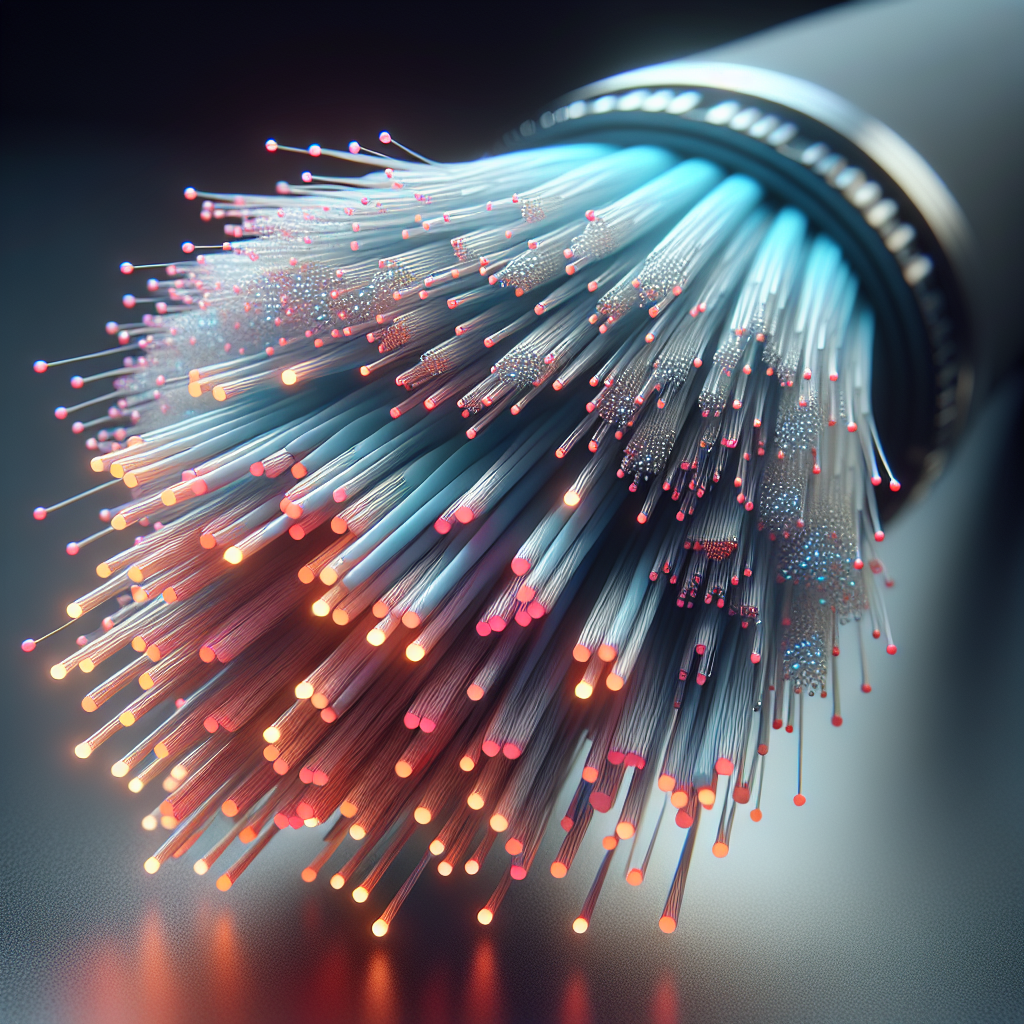

Protective Layers and Materials

Fiber optic cables are known for their durability and efficiency, and much of this is due to their robust protective layers and materials. These layers are meticulously designed to safeguard the delicate core and cladding from physical damage, environmental factors, and signal interference.

One of the primary protective layers is the buffer coating. This layer is applied directly over the cladding and serves as the first line of defense against external damage. It is typically made of a soft plastic material that provides a cushion, protecting the core from mechanical stress and microbending losses.

Outside the buffer coating is the strength member, which is crucial for maintaining the cable’s structural integrity. The strength member can be made from materials such as aramid yarn (often known by the brand name Kevlar), steel wires, or fiberglass. Aramid yarn is particularly popular due to its high tensile strength and lightweight nature, which helps the cable withstand pulling forces during installation without stretching or breaking.

The outermost layer is the jacket, which encases all the inner components. The jacket is usually made from plastic materials like polyethylene (PE), polyvinyl chloride (PVC), or thermoplastic elastomers (TPE). These materials offer excellent resistance to environmental hazards such as moisture, chemicals, and extreme temperatures. Additionally, the jacket can be designed with extra features like UV resistance for outdoor applications or flame retardancy for safety in indoor installations.

In some specialized fiber optic cables, additional protective layers may be included, such as water-blocking elements, armor for rodent protection, or extra jacketing for increased abrasion resistance.

The combination of these protective layers and materials ensures that fiber optic cables can deliver reliable performance even in harsh conditions, making them a vital component in modern communication infrastructure.

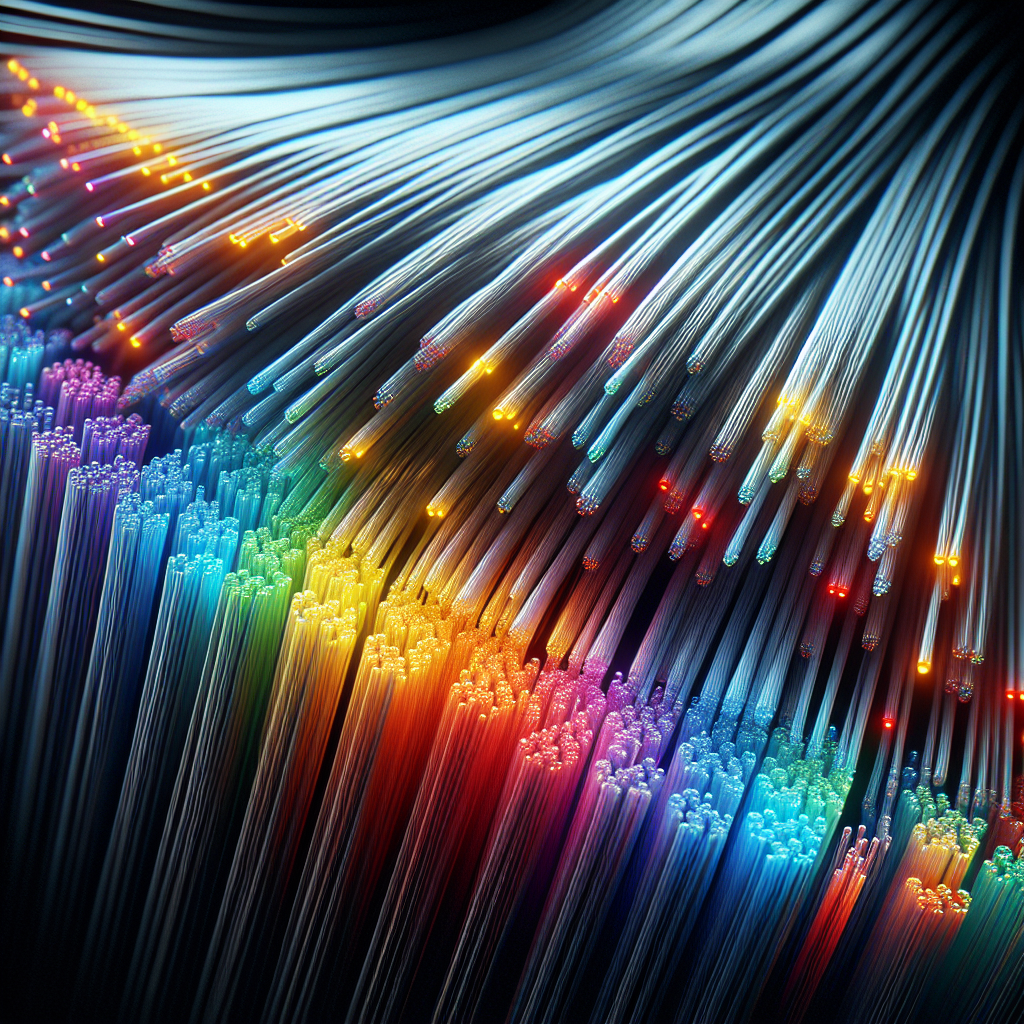

Types of Fiber Optic Cables

Fiber optic cables come in a variety of types, each designed to meet specific needs and applications. Understanding the different types can help you make informed decisions for your business or residential infrastructure.

Single-mode fiber (SMF): This type of fiber optic cable is designed to carry light directly down the fiber. It has a small core size, typically around 9 micrometers in diameter, and is used for long-distance communication with minimal signal loss. Single-mode fibers are ideal for telecommunications, internet, and cable television services because they provide high bandwidth over long distances.

Multi-mode fiber (MMF): Unlike single-mode, multi-mode fibers have a larger core size, usually around 50 or 62.5 micrometers in diameter. This allows multiple modes or paths of light to travel down the fiber. While multi-mode fibers are not suitable for long-distance transmission due to modal dispersion, they are excellent for short-distance communication, such as within a building or on a campus. They are commonly used in data centers and local area networks (LANs).

Loose-tube fiber: This type of cable is designed for outdoor installations. The fiber strands are housed in a loose tube filled with a water-resistant gel to protect against moisture and environmental conditions. Loose-tube fibers are typically used in aerial and duct installations and are known for their durability and ruggedness.

Tight-buffered fiber: Unlike loose-tube fibers, tight-buffered cables are designed for indoor applications. The individual fibers are coated with a buffer material that provides extra protection and makes the cable easier to handle. These cables are used in building risers, plenum spaces, and other indoor settings where flexibility and ease of installation are crucial.

Armored fiber: For environments where cables are exposed to physical damage or rodent attacks, armored fiber optic cables offer an extra layer of protection. These cables have a metal sheath, usually made of steel or aluminum, which enhances their durability and resistance to external threats.

By understanding the different types of fiber optic cables, you can choose the right one for your specific application, ensuring optimal performance and reliability for your communication needs.

Applications of Fiber Optic Cables

Fiber optic cables have revolutionized communication and technology across various sectors due to their superior performance, reliability, and efficiency. Here are some of the key applications of fiber optic cables:

Telecommunications: Fiber optic cables are the backbone of modern telecommunication networks. They enable high-speed internet, telephone services, and cable TV by transmitting large amounts of data over long distances with minimal signal loss. The high bandwidth and low latency make them ideal for supporting the growing demand for data and video streaming services.

Internet and Broadband: One of the most common uses of fiber optic cables is in providing high-speed internet connections. Fiber-to-the-home (FTTH) and fiber-to-the-premises (FTTP) installations deliver faster and more reliable internet services compared to traditional copper cables. This application is essential for both residential and commercial users who require robust internet connectivity for daily operations.

Data Centers: In data centers, fiber optic cables are used to connect servers, storage systems, and networking equipment. Their ability to handle high data rates and long-distance transmission makes them perfect for managing the vast amounts of data processed in data centers. This ensures efficient data transfer, reduced latency, and enhanced network performance.

Healthcare: Fiber optics play a crucial role in the medical field, particularly in imaging and diagnostic equipment. They are used in endoscopes, surgical instruments, and other medical devices to provide clear and precise images, aiding in accurate diagnosis and treatment. Additionally, fiber optic networks in hospitals support high-speed data transfer for electronic medical records and telemedicine services.

Industrial Applications: In industrial settings, fiber optic cables are used for communication and control systems. They are resistant to electromagnetic interference and harsh environmental conditions, making them suitable for factory automation, robotics, and process control. Fiber optics ensure reliable and secure data transmission in these critical applications.

Military and Aerospace: The military and aerospace sectors utilize fiber optic cables for secure and high-speed communication. Their lightweight and durable nature makes them ideal for use in aircraft, ships, and other military equipment. Fiber optics provide secure data transmission, which is crucial for defense and aerospace operations.

Fiber optic cables have become indispensable in our modern world, providing the foundation for various applications that require reliable and high-speed communication. Visit our website to learn more and get started today! Click here.